Paraformaldehyde 92% and 96%

Paraformaldehyde possesses the common characteristics with a wide range of applications

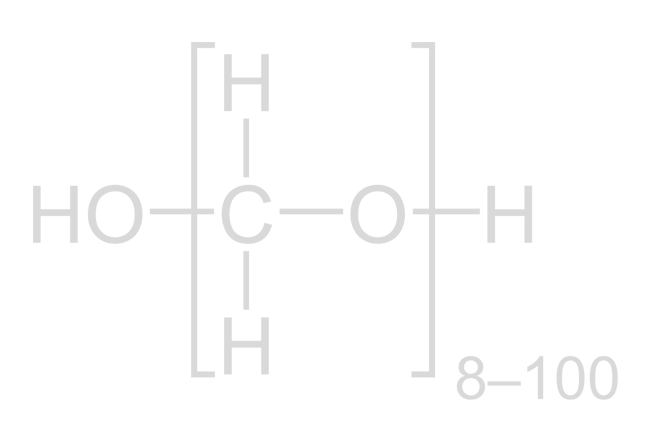

Paraformaldehyde is the smallest solid form of liquid formaldehyde, formed by the polymerization of formaldehyde with a typical degree of polymerization of 8-100 units. As paraformaldehyde is basically a condensed form of formaldehyde, it possesses the common characteristics with a wide range of applications.

Packaging & Handling

HDPE bag: 25 KG net.; 500kg jumbo bags Other packaging sizes by request.

Advantages of paraformaldehyde in resin production

as compared to aqueous formaldehyde

Paraformaldehyde does not need to be dissolved in water in order to take part in a chemical reaction.

Higher productivity from existing equipment and less water to be removed from the resin product.

Paraformaldehyde made with very low acid content in a chemical resistant environment can prevent the formation of acidic by-products.

We offer a prilled form, which is stable and very easy to store. Paraformaldehyde storage is less expensive than the storage of formaldehyde solution, which requires expensive tanks and which may need stabilization or be kept warm.

It eliminates the risk of transporting liquid formalin, which is notoriously dangerous. Perfect for small uses straight from the bag.

Use of paraformaldehyde is convenient and safe. It avoids pollution arising from the disposal of the distillate obtained in the thermosetting resin production which is contaminated with organic matter.

Typical Properties

| Color | White |

| CAS Number | 30525-89-4 |

| Appearance | Free Flowing Prilled |

| Molecular Formula | OH-(CH2O)n-H where n=8 to 100 units |

| Paraformaldehyde Content | 92% ± 1% / 96% ± 1% |

| Water Content | 8% ± 1% / 4% ± 1% |

| Reactivity | 2 – 8 min |

| Mean Particle Size | 250 – 350 µm |

| Ash | 0.01 – 0.05% |

| Bulk Density | 650 – 850 kg/m3 |

| Melting Point | 120 – 175 C |

| Ph | 4 – 7 |

| Flammability | combustible, with flash point (tag open cup) of about 93 C |

| Vapour Pressure | varies with air humidity, being between 23 and 26 mmHg at 25 C |

Applications

Resins Industry

The most important use of paraformaldehyde is as a source of formaldehyde groups in the production of many thermosetting resins, together with phenol, urea, melamine, resorcinol and other similar reagents. These resins are used as moulding powders; in the wood industry as glues for chipboard, plywood and furniture; as bonding resins for brakes, abrasives and foundry dyes; as finishing resins for paper and textiles; as driers and glossing agents for paints; as insulating varnishes for electrical parts.

Disinfectant

Paraformaldehyde generates formaldehyde gas when it is depolymerized by heating. The depolymerized material reacts with the moisture in the air to form formaldehyde gas. This process is used for the decontamination of large spaced and laminar-flow biological safety cabinets when maintenance work or filter changes require access to the sealed portion of the cabinet. It is used in the poultry industry as a disinfectant in the hatcheries, and cattle and sheep industry for sanitizing the bedding in the sheds. It releases formaldehyde gas when the temperatures increase. It reduces contamination levels caused by moulds, viruses and bacteria.

Agriculture and Pesticides

Most paraformaldehyde consumed by the agrochemicals industry is for the herbicides such as bismerthiazol, butachlor, acetochlor, glyphosate, and machete.

Embalming Process

Formalin is used during embalming processes as a disinfectant and preservative. It is used as an injection fluid in arterial and cavity embalming, and in surface embalming as a fluid for soaking surface packs or a gel applied to the skin or internal surfaces. Paraformaldehyde, a powdered polymer form of formaldehyde, is also sometimes used in embalming processes.

Reagent for Organic Reactions

In microbiology laboratories, fixation process (immunofluorescence) uses formalin 4% concentration. A blog by researchers mentioned that preparing this solution “fresh” from paraformaldehyde is better than using formalin that has been kept for some time. It is because more methylene glycol is present compared to its dimer and trimer oligomers and such solution of formalin 4% is absent of methanol.

Oil Well Drilling Chemicals

Paraformaldehyde is used in the manufacturing of 1,3,5-triazine used as H2S scavenger in Oil drilling process.

Get in Touch

Phone: +91-22-28885544 / +91-22-40045577

Fax: +91-22-28885533

Cell: +91-9821038477/ +91-9920384771

info@mribchemicals.com

Open Hours

10 am - 6 pm (Mon-Sat)

Address:

MRIB CHEMICALS

432-433, New Sonal link Indl. Estate, Bldg no. 2, Link Rd., Malad (W),

Mumbai – 400064. India